Cement Manufacturing

Powered by the advanced QIR algorithm, our system not only predicts the remaining life of the refractory but also recommends the optimal time for replacement. After every kiln shutdown, QIR performs a detailed scan to update thickness data and continuously refine its predictive capabilities, maximizing your kiln's efficiency and performance.

Extend Production Days

Reduce the risk of unplanned shutdowns and extend the number of days your kiln can operate.

Reduce Maintenance Costs

Replacing refractory at the optimal time can significantly reduce maintenance costs.

Maximize Kiln Lifespan

Reduce and eliminate hot spots and thermal shocks that can damage refractory.

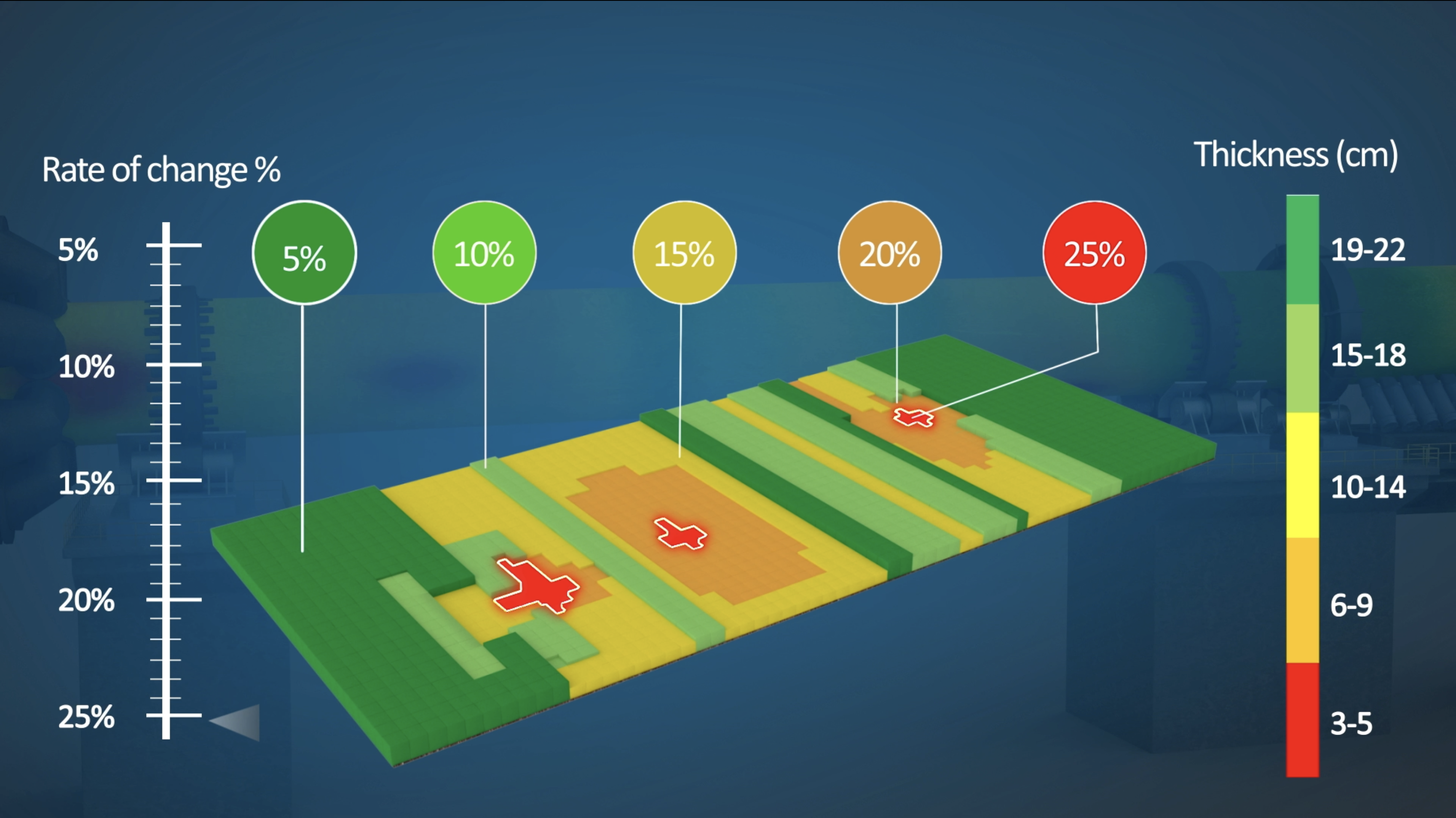

Kiln Predictive Refractory Brick Thickness Analytics

Our cutting-edge technology provides highly accurate measurements of refractory brick thickness, including the coating on the burner side, ensuring extended refractory lifespan and minimizing the risk of unplanned shutdowns.

- Real-time details on the brick thickness of the complete kiln

- Artificial Intelligence Based Algorithms

- Maximizes the useful life of refractory lining

- AI Algorithms that use 3D modeling to optimize accuracy

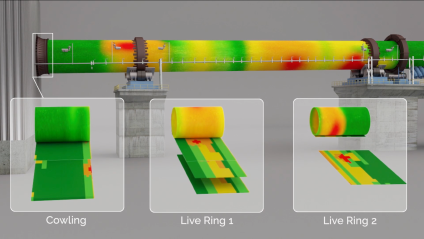

Kiln Live Rings and Cowlings Analytics

QIR cement solutions provide a complete view of the kiln. The high definition IR cameras monitor and record the entire surface of the kiln, including areas under the live rings and cowling/nose ring. Other cement kiln monitoring solutions do not give this comprehensive view of the entire surface as well as hidden areas under live rings a nose ring.

- Real time brick thickness analytics of the whole kiln - including live rings and cowling

- Reduces days the kiln is down for maintenance

- Reduces kiln maintenance costs

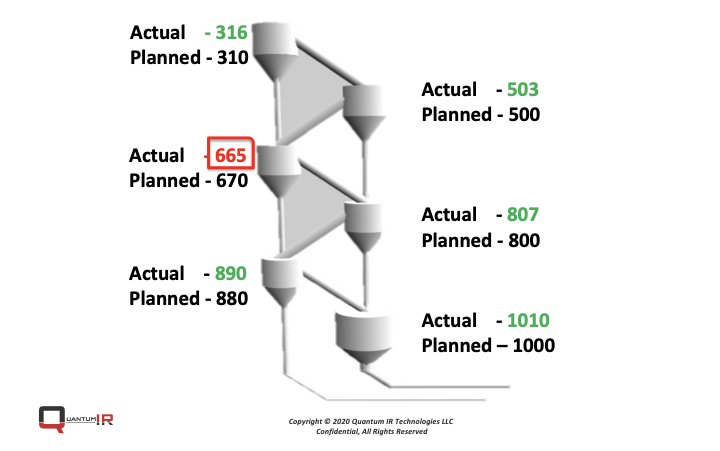

Preheater Thermal Performance Management

Provide updated temperature performance over any time period.

- Monitor real time temp at each level

- User defines optimum temps at each level

- Alerts if deviation from optimum temp

- Algorithms provide temp correlation between levels

- Preheater temps correlated to expected kiln input temp

- Historical analysis provides temp performance over any time period

Start reducing your risk today

Try QIR to reduce your risk and improve your operations

Get started today