Customers Success Stories

Industry leading customers worldwide

Our customers include global cement companies, major global oil & gas companies, leading steel manufacturing companies, large power generation companies, and US Federal and State agencies.

Customer Story #1 - Northrop Grumman

Northrop Grumman is an American global leader in aerospace and defense technology with a market cap of $49.71 Billion in 2021. It is one of the world's largest weapons manufacturers and military technology providers.

The Project

The Research Operations Group at Northrop Grumman is involved in many different projects involving machining such as remote milling, lathe cutting, and diamond wire saw cutting. Often these machining operations are performed on objects that are temperature sensitive, or even temperature critical devices such as a live energetic propellant cartridge for a D5 test motor. During these operations it is imperative to ensure that maximum temperatures are not exceeded for the integrity of the device under test, and for the safety of the lab and personnel.

Bryan Smith from Northrop Grumman has been an Energetic Staff Engineer in the Research Operation Engineering for the past 30 years and has managed numerous projects. Bryan and the group are always looking for ways to improve productivity and increase the safety of their processes. Bryan said his challenge was finding a simple, easy to use program to monitor temperatures of the process in real time. His motivation to solve the challenge was to make it easier and more reliable for the machinists to perform their job.

Infrared cameras are used to monitor the machining tools and objects being machined to ensure critical temperatures are not exceeded. Quantum IR Technologies (QIR) worked closely with Bryan and his team to determine their needs and craft a solution that allows them to have a clear view of the temperatures generated during the machining process in real time. In addition, QIR software logs all data and provides historical views of every operation for future review. It also allows for historical data analysis over many operations to help improve future work, and to provide forensic analysis of past operations.

In Bryan’s words “QIR solutions gave us a clear view of the temperatures generated, providing an effective way to monitor processing temperatures in real time. The tools are easy to use and reliable. Quantum IR is knowledgeable about their product, can tailor it to our specific needs, and is very responsive. QIR solutions helped us achieve and improve performance, be more reliable, safer, and better able to control operations”.

-

Picture via Northrop Grumman

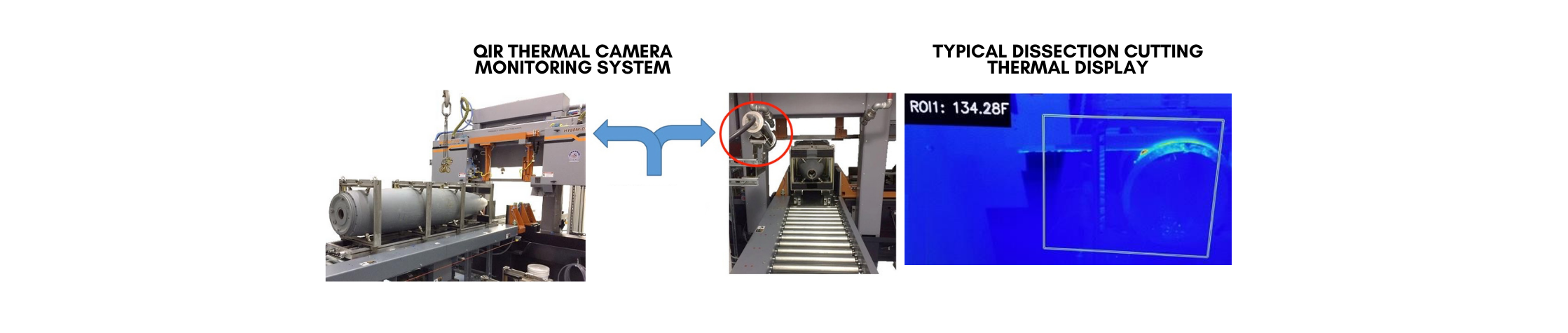

Northrop Grumman IR Camera Use

The IR Camera is used to monitor temperatures during remote milling, lathe cutting, and diamond wire saw cutting. This is to ensure temperatures not exceeded process requirements.

Quantum IR Technologies solution has a clear view of the temperatures generated, provides an effective way to monitor temperatures in real time, easy to use , and reliable system.

Quantum IR is knowledgeable and can tailor to your specific needs. They are very responsive. I recommend that any process that requires real time or continuous thermal monitoring should consider using Quantum IR technologies.

Customer Story #2 - General Purpose Munitions Group - Northrop Grumman

The General Purpose Munitions (GPM) Group at Northrop Grumman (NG) is involved in Aging & Surveillance inspections of a variety of munitions within the US arsenal.

The Project

Dennis Tolman, a Project / Process Engineer at Northrop Grumman, with over 30 years of energetic material fabrication, handling & processing experience, is currently responsible for all large munition dissection processes at NG’s Promontory Plant.

When setting up this new capability in 2017, as the dissection process is a heat generator, the need for temperature interlock controls on the equipment was immediately recognized, and NG turned to Quantum IR to design the needed system.

The QIR system installed on the dissection saw provides real-time feedback to the PLC controlling the cutting process. As the saw cuts its way through the munition, this real-time data is displayed for personnel surveillance on a control monitor. If temperatures begins to rise, operational adjustments can be made to quickly reduce the processing temperature. Preset limits also prevent the saw from operation if those limits are reached. Historical trend temperature data is also tracked and recorded for later evaluation by the Engineering team.

This system has proven to be easy to understand, and user friendly to operate. NG credits the QIR system for allowing a very hazardous process to be safely carried out. There have been no temperature related issues on this process since production work began in 2018.

Picture via Northrop Grumman LinkedIn

We simply cannot operate without QIR solutions. If our processing temperatures were to exceed the control limits defined (as monitored by QIR), there would be a catastrophic fire, severely damaging the process equipment or area. QIR Solutions provide robust and thermal monitoring solutions - where thermal controls are an issue.

Quantum IR Technologies has a great team to work with, and always very responsive when follow-up or system upgrades have been needed. I would have NO problem recommending QIR Solution as a thermal control system provider.

Please Contact Us.