Kiln Predictive Refractory Brick Thickness Analytics

Extend useful life of kiln refractory

Kiln Predictive Refractory Brick Thickness Analytics

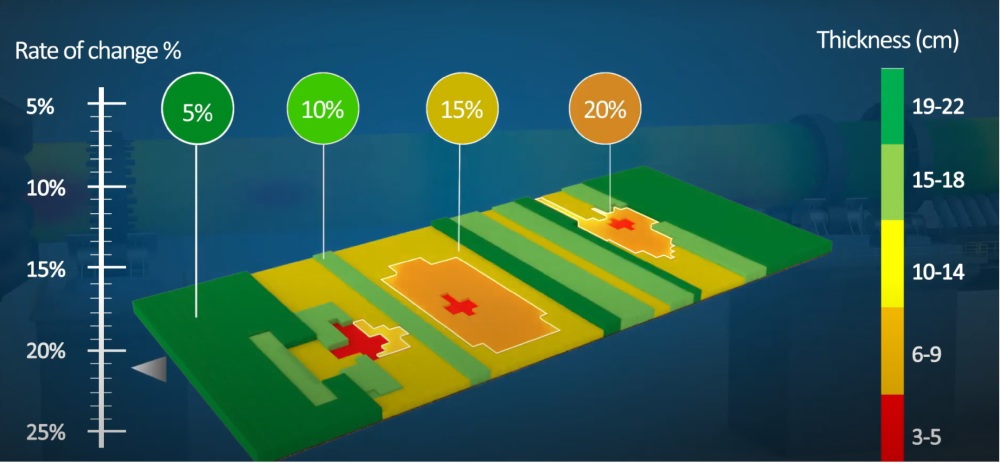

Provide real-time details on the brick thickness of the complete kiln to

alert the operators on rates of reduction in brick thickness and the corresponding increase in

energy to maintain optimum kiln temperatures and resulting additional CO2 emissions of the kiln.

- After several shutdowns for maintenance QIR AI algorithms become very accurate in predicting brick thickness and operational time that can be used in the future

- QIR AI Algorithms use 3D model to optimize accuracy.

- Maximizes the useful life of refractory lining.

- Increase revenue and profit by increasing production days and Reduce the days the kiln is down for maintenance.

- After several shutdowns for maintenance QIR AI algorithms become very accurate in predicting brick thickness and operational time that can be used in the future

Quantum IR Technologies offering solutions for kiln refractory predictive brick thickness, providing high precision refractory thickness (including coating on burner side), so it will extends refractory useful life without risking unplanned shutdown.

QIR algorithm also have ability to predicts life of refractory and suggests optimum timing for replacement. And each time during kiln shutdowns, QIR will scan kiln to update thickness and improve algorithm.

https://www.youtube.com/watch?v=RwBM3rbarHs